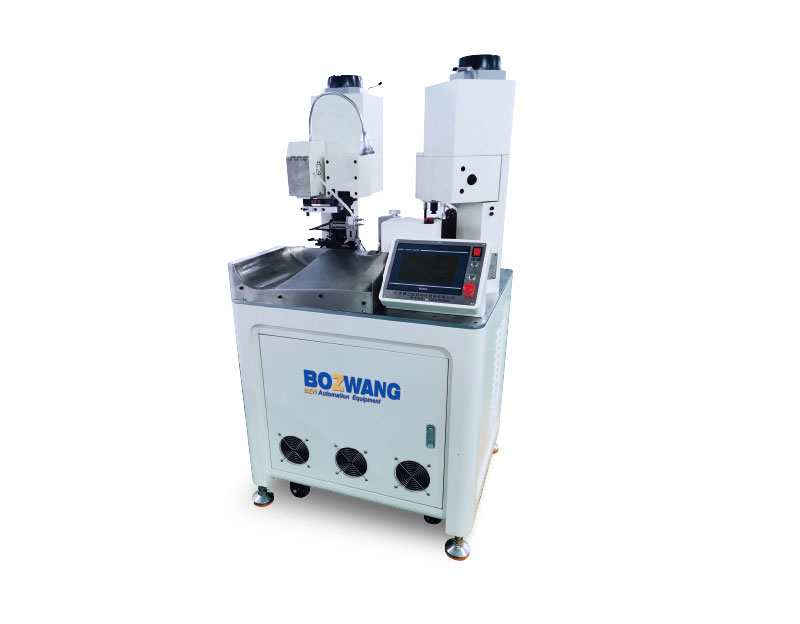

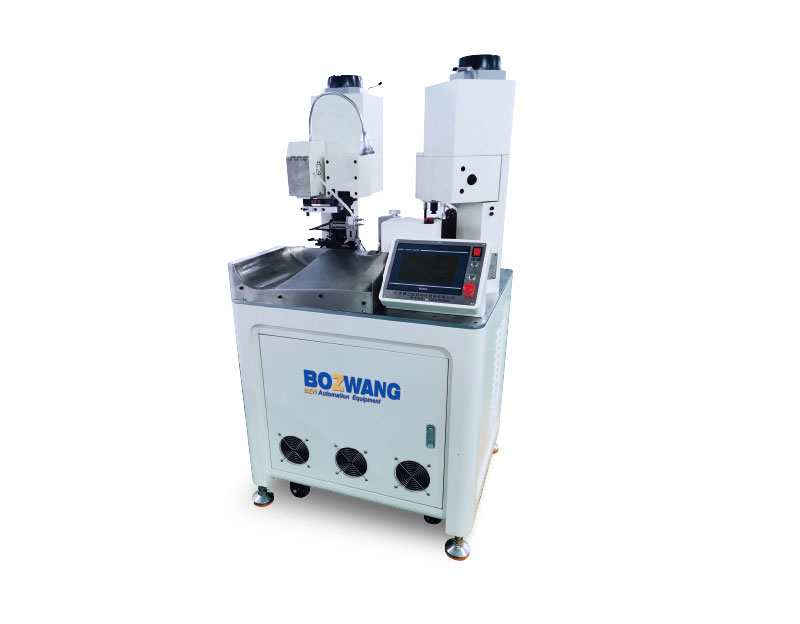

Product Feature:

1.PLC control system, double ends terminal crimping can be finished at one time;

2.Exquisite, compact design, tight space, excellent idea;

3.Computerized touch screen, using DSP microcontroller menu, easy to learn;

4.Quick process to replace materials; fully digital debugging. Convenient in maintenance;

5.Efficient stepping drive, high precision and speed;

6.High cost performance. All pneumatic components are from Japan SMC, Taiwan power switch, Taiwan HIWIN guide rail.

Technical Parameters :

| BZW-2.0 | Automatic double ends terminal crimping machine |

| Wire range | 0.3-2.5 mm2 (For 4 and 6mm2 cable cutomerized made) |

| Cutting length | 45-9999mm |

| Cutting precision | ±(0.2%*L+1)mm |

| Stripping length | 0.1mm~10mm |

| Feeding speed | Max 3.0 m/s |

| Capacity | 3000-3500pch/h(length≤100mm) |

| Crimping force | 20KN (Other can be customized) |

| Power | AC220V/50/60HZ |

| Motor | 2.2KW |

| Air supply | 4~6kg (Dry and clean air) |

| Weight | About 358kg |

| Dimension | 700 x 800 x 1500mm |

| Function | Wire cutting and stripping and terminal crimping on both ends . |

| Detection device | Wire lacking test, terminal crimp pressure test, wire knotting test, air pressure test, CFM device is optional . |

| Applicator range | Stroke 30mm (40mm stoke can be special ordered) |