Degree of automation:Automatic

Transport package:Wooden Case

Specifications:700*500*430mm

Certificate:CE/ISO:9001/ISO45001

Trademark:bozhiwang

Country of origin:Changzhou, China

0

0

The BZW-3.0 series automatic terminal crimping machine adopts an open 4-station platform design and is equipped with reliable EtherCAT technology to realize a high-precision flexible processing platform. The self-developed PC operating system realizes the graphical display of the interface, which is simple and easy to understand, and the information and data collection during processing provides a good foundation for the traceability, management and control of production quality and the docking of the MES system.

1.International appearance design, and tight and concise whole structure;

2.The flexible wire feeding system is used to ensure that the wire is not damaged while ensuring the wire length accuracy;

3.The crimping machine adopts a servo system to ensure the stability and consistency of the crimping accuracy;

4.PC operation interface, graphical display makes the operation more intuitive and simple;

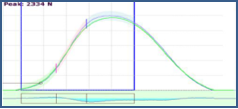

5.Embedded pressure management system can monitor the product in real time, alarm and automatically remove defective products;

6.The production processing parameters can be stored to realize fast switching of small batch orders

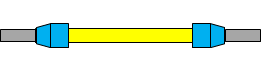

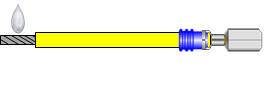

| Wire cutting |  |

| Half stripping |  |

| Stripping |  |

| Crimping |  |

| Seal inserting |  |

| Pre-insulated terminal crimping |  |

| Twisting and Tinning |  |

| Ultrasonic welding |  |

| Housing inserting |  |

| Inkjet printing |  |

| Pressure monitoring |  |

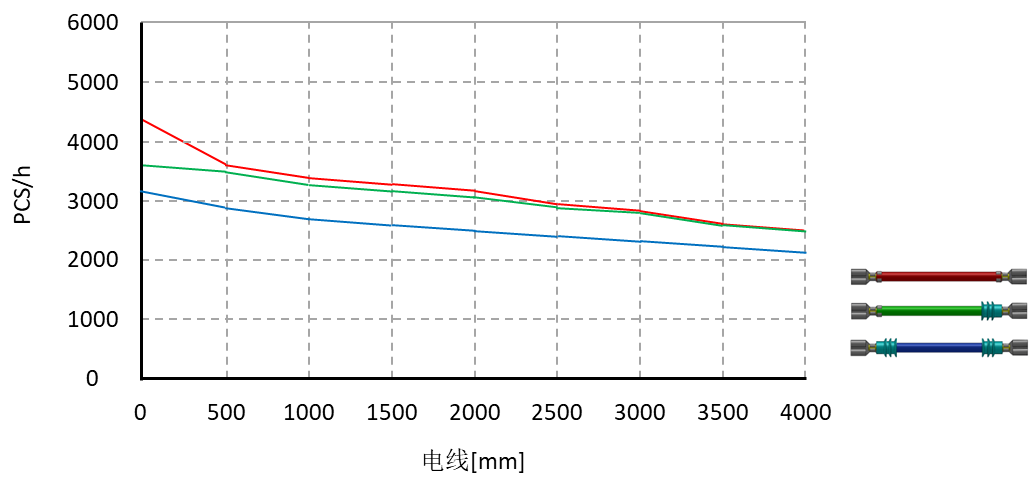

| Cutting length | 80-20000mm |

| Cutting precision | ±(1.0mm+0.2%*L) |

| Stripping length | 0.1-15.5mm |

| Wire range | 0.22-6mm² |

| Feeding speed | 12M/S(max) |

| Crimping force | 25KN |

| Wire receiving | 2m(Standard),4m ,8m |

| Noise | <75dB |

| Power supply | AC220V 50/60Hz 3.5kw |

| Air supply | 0.5-0.8Mpa |

| Air consumption | 6.5-8m³/h |

| Dimension | L3500 x W1200 x H1700mm(2m wire receiver) |

| Weight | 1100Kg |