Product Feature:

1.PLC control to ensure the stability of the each procedure;

2.Touching screen operation, the parameters of cutting length, cutting depth and wire tinning are all digital setting (full stripping or half stripping);

3.High precise sliding rail from Tai Wan, even tinning effect, which is suitable for long time working;

4.High precise Mitsubishi servo smotor, long service life, high precision and stable running;

5.Imported pneumatic, stable transmission and long life service;

6.The wire feeding system can be equipped.

Technical Parameters :

| BZW-887 | Automatic wire cutting, twisting and tinning machine |

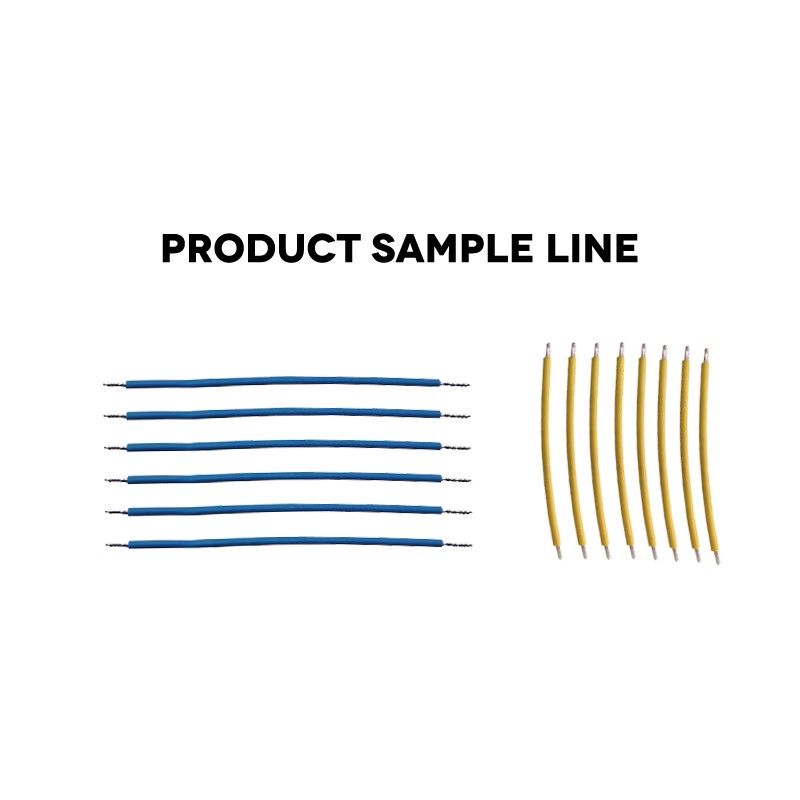

| Applicable wire | Pin, flat ribbon, enameled wire,twisted wire |

| Cutting length | 40mm-650mm (longer length can be customized) |

| Stripping length | 1-15mm |

| Twisting length | 3-15mm |

| Tinning length | 0.5mm-15mm |

| Capacity | 7000-8000 pcs/h (wire length 100mm) |

| Air pressure | 0.5Mpa |

| Function | Wire cutting, single end stripping, double ends stripping, single end tinning, double ends tinning, single end twisting, double ends twisting, single end half stripping, double ends half stripping, English and Chinese can be switched. |

| Power | AC 220V/50/60HZ, single phase 1300W |

| Dimension | 1500 x 800 x 1500mm |

| Weight | About 300KG |