0

0

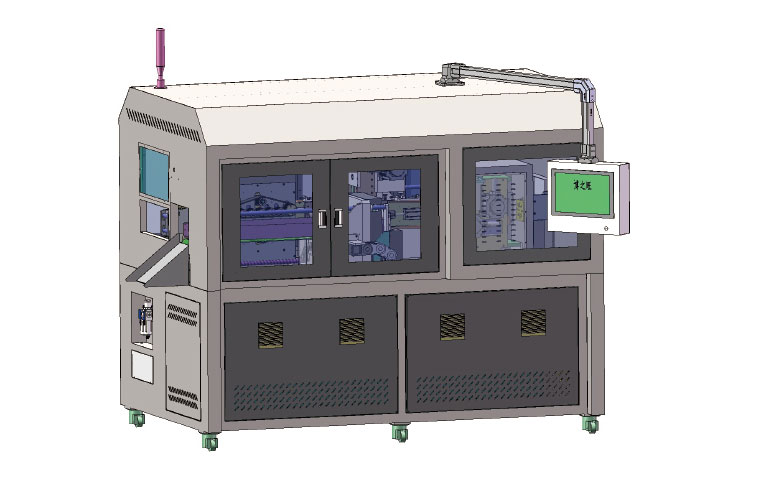

1.New mode cable processing equipment that controlled by micro computer, especially for processing the high voltage power cable in the industry of new energy motor, power charging station, electronic control, BMC and etc, which essentially solves the problem in processing the big power cable;

2.This machine adopts two groups of rotary cutter heads, and uses servo motor and ball screw to control the rotary cutter;

3.Automatic wire cutting, two ends stripping, and multi-layers stripping at one time;

4.PLC control system, touch screen operation mode, Inputting processing parameters can save the program, providing flexibility and convenience for production;

5.The wire diameter is automatically adjusted, and there is no need to change the cutter for cables of different specifications;

6.It can interface with the input and output of auxiliary equipment signals ;

7.The cable (within 400 mm²) can be easily processed,the strong driving force ensures the high working efficiency;

| Wire range | 20-240mm² |

| Cutting length | 1000-99999.99mm |

| Stripping diameter | ≤φ50mm |

| Stripping length | 5mm-800mm |

| Drive | 8 wheels independently servo driven |

| Capacity | 200-300 pcs/h |

| Power | 220V 50/60HZ |

| Motor | 5.5KW |

| Stored procedure | 0-99 kinds of processing data |

| Tool materials | Imported high speed steel |

| Appied diameter | Φ20-50mm |

| Press wheel setting | Motor drive, digital control of crimping force |

| Air pressure | 0.5-0.8mpa |

| Stripping layer | 6 layers |

| Dimension | 2440 x 1560 x 2100mm |