0

0

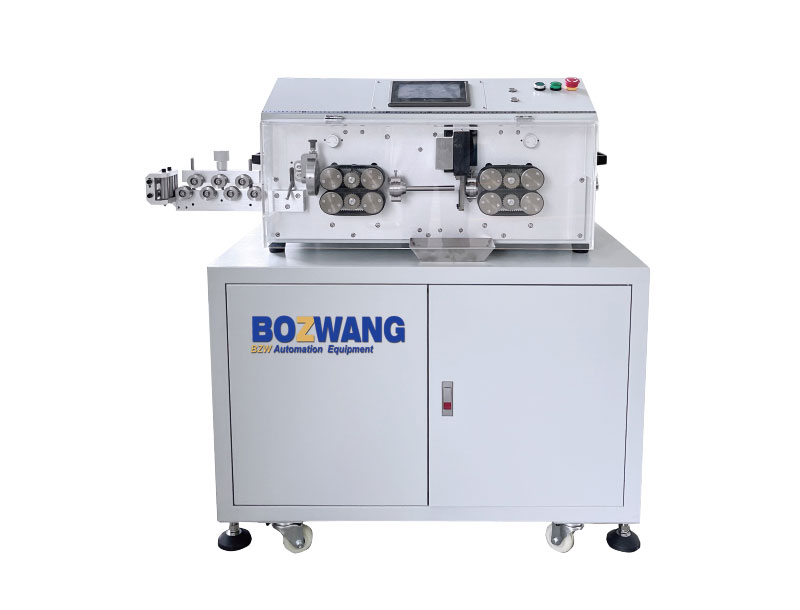

1. This machine is a new type of cable processing equipment controlled by microcomputer, which is mainly aimed at the processing of new energy, photovoltaic, communication, electronic control, high-voltage power lines and multi-core sheathed cables. The introduction of this model completely solves the processing difficulties of large square wires and multi-core sheathed cables;

2.Automatic cutting and peeling of insulation at both ends, and multi-layer peeling processing at the same time;

3.Industrial control chip with high-precision servo drive makes the machine stable and high-speed operation;

4.PLC control system, touch screen operation mode;

5.Belt driven, no indentation;

6.Customized servo drive and configurable cabinet.

| Peeling diameter | ≤Φ14mm |

| Stripping range | 4-50mm² |

| Cut length | 0.1-99999.99mm |

| Length accuracy | ≤0.2%mm |

| Stripping Length | Strip 1-200mm at the end of the line and 1-100mm at the end of the line |

| Driving mode | 8-wheel independent servo drive |

| Yield | 800-1000 pcs/h (It depends on the length and size of the line) |

| Power Supply | 220V 50/60Hz |

| Motor power | 1.2KW |

| Storage procedure | Processing data of 0-99 kinds of cables |

| Blade material | Imported high speed steel |

| Conduit diameter | Φ6-14mm |

| Pressure | 0.2-0.6mpa |

| Peeling layers | 3 layers |

| Weight | 120kg(Excluding cabinet) |

| Overall dimension | 800 x 650 x 430mm |